The biggest Scaffolding manufacturer in China with high quality.

WHY CHOOSE CUPLOCK SCAFFOLDING?

◆ High Standard Process: Q235 / Q345 ERW, three coating painting surface enhancing her corrosion resistance; 15 years lifespan.

◆ Multi-functional usage: Adapting to all kinds of construction requirements, especially suitable for the erection of scaffolding and heavy propping.

◆ Quick erection, less time and effort: Maximum standard weight reaches 17.07kg, the erection and disassembly rate 3-5 times faster than the conventional scaffolding.

◆ High capacity load: stable and reliable structure with outstanding performance; the joint connector of cuplock can resist high bending, shearing and torsion, with load capacity 15% more than traditional tubular & fitting scaffolding system.

◆ Safe and reliable: Three-dimension axial force express and structure of the scaffold can create high strength, good stability and perfect auto-lock and meet the requirement of safe construction.

◆ Maintenance &management free-trouble: No loose accessories, complete system easy to manage during construction.

CUPLOCK SYSTEMS MAIN COMPONENTS

CUPLOCK DIAGONAL BRACE

Each brace has swivel blade ends to allow for easy location within the node joint.

As only one blade end can be located in each joint, parallel bracing is employed.

| Code | Item Name | Material(mm) | Length(m) |

| ADTO0WKMG0002 | DIAGONAL BRACE | Q235/Q345, 48.3*3.2mm | H1.5 L1.8 |

| ADTO0WKMG0003 | H1.5 L2.5 | ||

| ADTO0WKMG0004 | H2.0 L1.8 | ||

| ADTO0WKMG0005 | H2.0 L2.5 |

ADTO CUPLOCK SCAFFOLDING SYSTEM

ADTO PRODUCTION EQUIPMENT

CUPLOCK PACKING & LOADING

ADTO SCAFFOLDING CERTIFICATES

ADTO CUPLOCK SCAFFOLDING APPLICATION

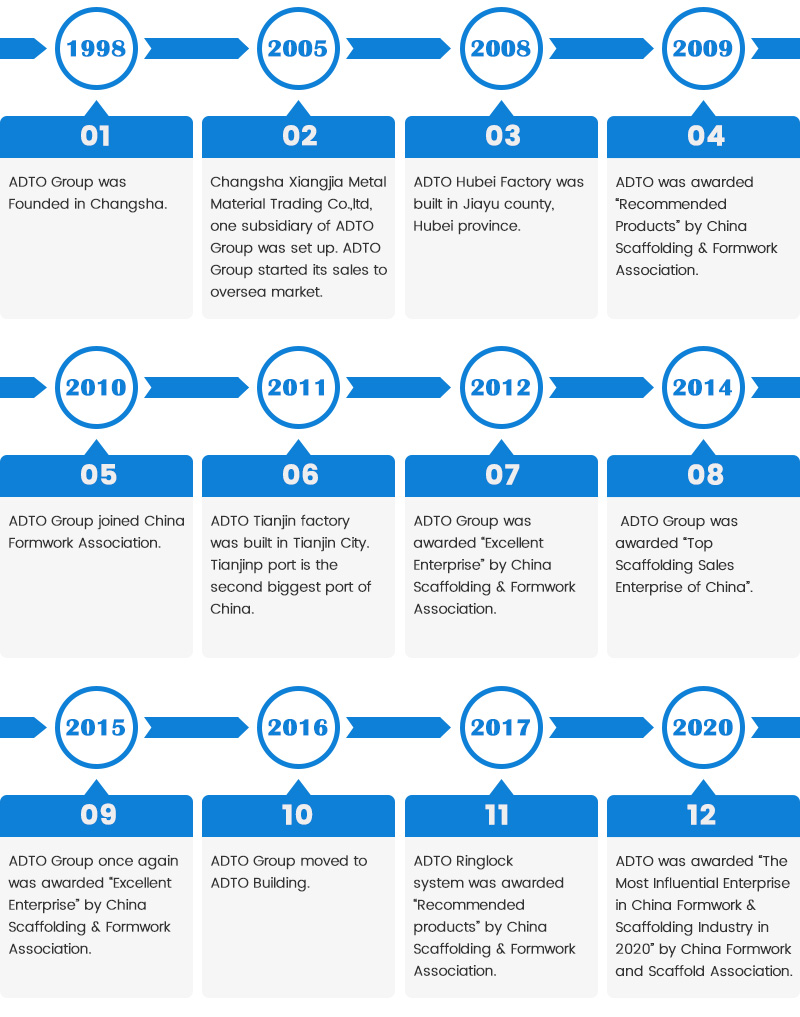

ADTO COMPANY PROFILE

EXHIBITION